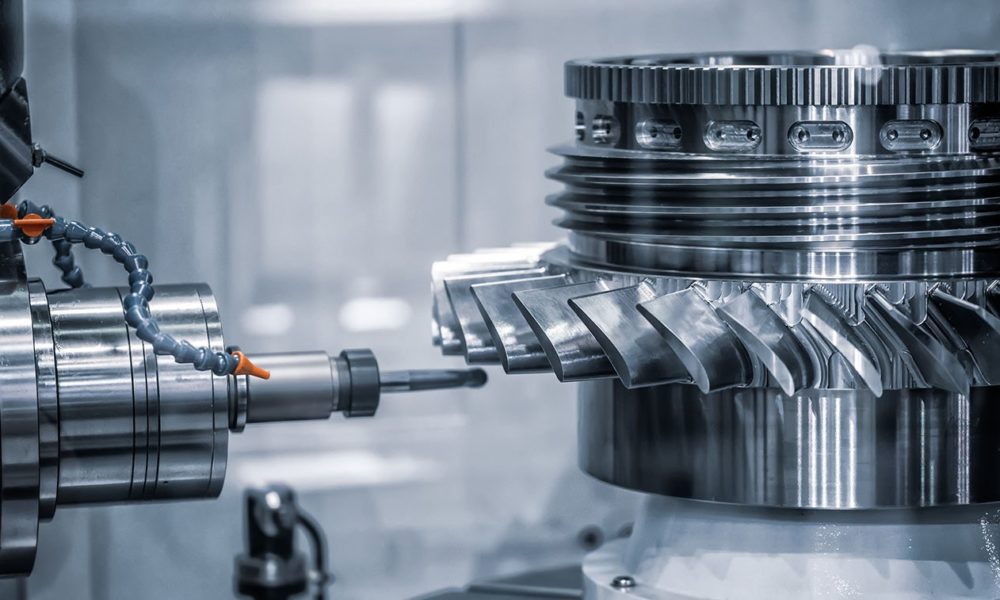

CNC machines provide many benefits dedicated to the production or manufacturing process. Accuracy and speed have always remained the main objective behind a CNC machine from those benefits. You might be aware of the prime benefits of a CNC machine.

However, likely, you might not know the top features of a CNC machine. Before diving into the characteristics of a CNC machine, you should check out precision CNC machining. CNC machines play an essential role in the industry. It would be vital for you to know the characteristics of CNC machinery mentioned below:

- Flexible

CNC machines are flexible with any workpiece or material. The flexibility factor of CNC machines allows them to proceed with multiple types of materials in various shapes of sizes. This feature will enable manufacturers to complete drilling, boring, reaming, tapping, milling surfaces, milling slopes, etc., within less time.

- Versatile

As we mentioned earlier, one of the top features of CNC machines is flexibility. The flexible functionality of CNC also allows many people to experience versatility without compromising on any factor. The compatibility of CNC machines will enable them to gain an extra edge in the overall procedure.

- Accuracy

You might likely have come across this feature. However, mentioning how accurate CNC machines are worth it. The software and the programs used in the recursive approach allow the industry to achieve accuracy and prevent defects.

- Efficiency

Efficiency is one of the primary features of CNC machines. CNC machines have the combinational feature set of a milling machine, boring machine, and drilling machine. These machines have different functions with maneuvering time. CNC machines provide an efficient way to cater to the demands.

- Complex shapes

Apart from processing materials at different speeds and times, you should also know that the machine needs to process the shape of the material. However, CNC machines can efficiently function or process materials of different shapes and sizes.

- Labor intensity

CNC machines are used to accomplish specific tasks with the help of programming and controlling systems. The machines can do multiple jobs like loading and unloading tools, observing the operation of the machine tool, measuring the materials, etc. Such tasks can be done without involving a human operator. Hence, CNC machines provide a feature to reduce labor intensity.

The top features of CNC machines might be intriguing. Human interaction and control in the industry or factory would be acceptable. But, CNC machines provide minimal to zero error, reduce labor intensity, cutting edge accuracy, etc. Such a set of functions makes it difficult not to use CNC machines.